Knowledge

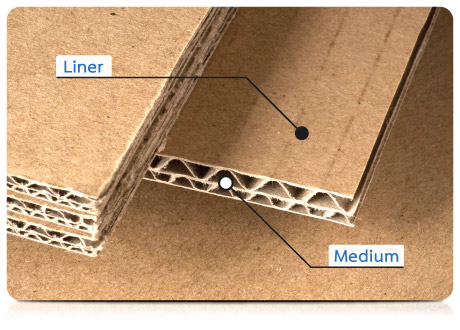

Corrugated board

consists of two main components

Linerboard :

is a thin cardboard used for the flat facing of the corrugated board.

Corrugating Medium :

is a sheet of paper that has passed through a corrugating machine to give it wavy ridges called flutes.

The strength of the two components affects the strength of the corrugated board.

Linerboard

KA

- Golden Yellow

- Maximum strength, excellent resistance to stacking loads and impacts, as well as high humidity resistance. Suitable for packaging of valuable and heavy products that require special strength and high confidence.

KI

- Bright Brown

- Natural light brown, superior strength, excellent resistance to impacts and stacking loads, and suitable for packaging with colorful prints.

KP

- Brown

- The color similar to shade of packaging widely used in America, or that being exported to the area. Superior strength, great resistance to impacts and stacking loads, and suitable for packaging of heavy products and exports.

KH

- Yellow Brown

- Clean and smooth surface. Greatest strength, excellent resistance to impacts and stacking loads, and suitable for electronic products and exports.

KT

- Brown

- Made entirely of recycled pulp, excellent resistance to impacts and stacking loads, suitable for eco-friendly products.

KS

- White

- Made of bleached and high-quality virgin pulp, this premium white top liner is specially devised for an ultimately clean look. Excellent resistance to impact and stacking loads, and good moisture resistance. Suitable for packaging of high value or hygienic products like frozen food, medical appliances, or luxury exports.

Corrugating Medium

CA

- High strength, easily applied with an adhesive.

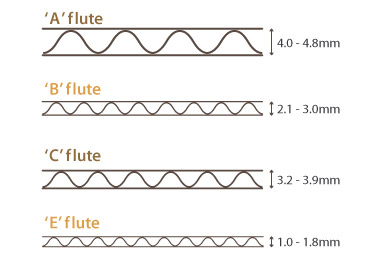

Generally,larger flutes have greater strength, and has better resistance to impacts, while smaller flutes are more suitable forquality printing and can be formed and folded more precisely. The flute type can be chosen depending on the usage and requirements of the users.

| Type | Height (mm) |

Number of flutes/ft |

Characteristics |

|---|---|---|---|

| A | 4.0 ‐ 4.8 | 36 | Excellent for compression and cushioning with good stacking strength, but does not enhance printing. |

| B | 2.1 ‐ 3.0 | 49 | Suitable for products that can support the stacking weight on its own, such as cans. |

| C | 3.2 – 3.9 | 41 | Most common flute used for general products that can support medium weight. |

| E | 1.0 – 1.8 | 95 | Best for quality printing, suitable for small die cut or offset boxes. |

| Properties | B | C | E |

|---|---|---|---|

| • Stacking | Average | Good | Poor |

| • Printing quality | Good | Average | Very Good |

| • Slitting | Good | Average | Very Good |

| • Puncture resistance | Average | Very Good | Poor |

| • Stocking | Average | Average | Poor |

| • Scoring | Good | Average | Very Good |

| • Impact and vibration resistance | Average | Good | Poor |

| • Bursting resistance | Good | Average | Average |

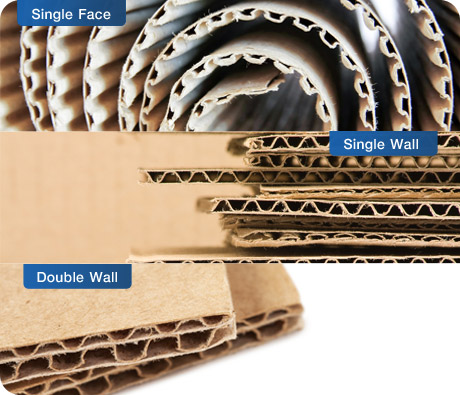

Single Face Board

- Consists of one ply of corrugated medium glued onto a linerboard. The fluted paper is exposed to outer surface. Commonly used for cushioning.

- Standard flutes: B, C, E

Single Wall Board

- One ply of corrugated medium glued between two plies of linerboard. Used for medium weight products.

- Standard flutes: B, C, E

Double Wall Board

- Two piles of corrugated medium glued together by three plies of linerboard. Used for products that are heavy or need high protection.

- Standard flutes: B, C

Basis Weight

- Total weight of a corrugated board. It correlates to the strength and quality of the board.

- Unit: grams per 1 square meter (g/m2)

Ring Crush Resistance

- Ability of a kraft paper held in a ring form to resist crushing. It correlates to the edge wise crush resistance, or the stacking ability.

- Unit: Newton (N) or kilogram-force(kgf)

Concora Crush

- Ability of a corrugating medium to resist crushing. It correlates to the flat crush resistance.

- Unit: kilogram-force (kgf)

Edgewise Crush Resistance

- Ability of a corrugated board to resist crushing. It correlates to the compression strength, or the stacking ability.

- Unit: kilonewtons per meter (kN/m)

Flat Crush Resistance

- Ability of the flutes in a corrugated board to resist crushing by force applied perpendicular to the surface of the board. It correlates to impact resistance.

- Unit: kilogram-force per 1 squared centimeter(kgf/cm2)or kilopascal(kPa)

Bursting Strength

- Ability of a corrugated board to resist constant pressure. It correlates to stiffness or the quality of the board.

- Unit: kilopascal (kpa) or kilogram-force per 1 squared centimeter (kgf/cm2)

Puncture Resistance

- Ability of a corrugated board to resist a puncture.

It correlates to stiffness of the board. - Unit: Jules (J)

Cobb Test

- Ability to absorb water of a corrugated board in a specified time, including other liquid such as adhesive, printing inks, etc. It correlates to the paper strength.

- Unit: grams per 1 squared meter (g/m 2 )

Compression Strength

- Ability of a corrugated board to resist compression on the box until the box deforms. It correlates to the strength of the box and stacking ability.

- Unit: Newton (N) or kilogram-force (kgf)

Moisture Content

- Weight of water in a kraft paper or a corrugated board.

It correlates to the strength of the box. The moisture content should be < 10%